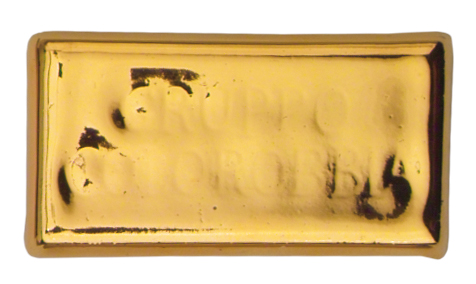

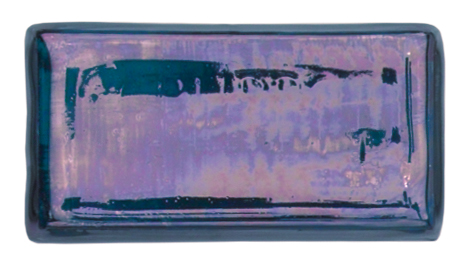

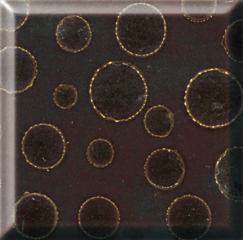

Liquid gold and metallic lustres have a colloidal form and have a dark brown colour; they contain dissolved metals as a main component.

PREPARATION-APPLICATION-FIRING

The products must be diluted with thinner HTL 199 in ranges from 5% to 15%.

They are mainly applied by brush on earthenware and porcelain. Airbrush application for professional use only. This application should always be on glazed objects; thoroughly clean and should be kept moisture free.

Before firing, allow items to sit in a dust-free, warm room for several hours to dry.

Firing temperatures:

Earthenware: 690°-700°C (Orton cone 018)

Porcelain: 750°-815°C (Orton cone 017-015)

GOLD AND PRECIOUS METAL LUSTRES FOR CERAMICS AND PORCELAIN

Certificates

All products are accompanied by the necessary documentation certifying their quality, characteristics and purpose.

Control

Continuous quality control and chemical analysis from raw material to final product.

Eco

The raw materials and additives used in the production are entirely natural products